Construction

EPIC Projects

Saifee Engineering is a well-established multi-disciplined Onshore and Offshore EPIC contracting company that has delivered EPIC projects for the State of Qatar since its inception. Saifee Engineering’s customer base includes Qatar Petroleum, Qatargas, Dolphin Energy, ORYX GTL, QAFCO, QAFAC, QAPCO, Q-Chem, and Q STec.Saifee Engineering has a capable team of experienced Project Management and Construction Management personnel overseeing the Engineering, Procurement, Construction, and Commissioning of projects.

Our in-house capabilities cater to the majority of project activities, and we aim to provide one-stop-shop services to our clients.Offshore works include activities such as boat landings, Electrical & Instrumentation upgrades, Brownfield Hook-ups on platforms, associated deck extensions, and MOC works undertaken by clients for process and production improvements.Onshore works include activities such as Electrical & Instrumentation upgrades, Process Plant upgrades including vessels, equipment, piping, and structures, associated civil works for plant upgrades, construction of buildings, and commissioning works across all disciplines.Saifee Engineering also undertakes sub-contract works for multinational clients (MNCs).

Our Cross-Country Pipeline portfolio consists of long-term contract with QP for installation of new pipeline of varying sizes from 6” to 30” and flow medium involving Engineering, Procurement, Installation and commissioning works. Our recent pipeline projects are “Dukhan Kuff Gas Flow Lines” (6” above ground) and “MIC FIFA Gasoline Pipeline” (30” Under Ground Pipeline in Sabkha area). 16” Jet Fuel line to NDIA is one of the EPIC Projects completed where numerous third-party crossing are executed in coordination with multiple government agencies. The Civil works involved pipeline works in sabkha area, Micro tunnelling works (Horizontal direct drilling) under High-way roads, Existing Pipelines and utilities in green filed and brown field area. We meticulously handle associated dewatering, lagoon building and related Environmental requirements. We give special focus on the specific external/internal coatings, downhill/uphill/dolly mix welding processes, lowering, Pipeline Pre-commissioning/commissioning works including the Base Line Survey works. We anticipate the risk of existing pipeline crossings, road crossings and fenced third party property crossings and initiate required early actions/approvals as required to meet the tight pipeline project schedules. Our work covers all disciplines not limited to Civil, Mechanical, Piping, Electrical, Instrumentation, Communication, Control System and Loss Prevention.

Saifee Engineering delivers major Brownfield and Greenfield projects to help our customers to get the most out of their assets. Over the past 40 years, Saifee Engineering has delivered a wide range of Brownfield and Greenfield Engineering, Procurement, Construction and Commissioning services to help our customers maximize efficiency, maintain asset integrity, and extend life for onshore and offshore assets.

Our Brownfield capability covers:

Major and minor shutdown management

Facilities upgrades

Major modifications

Compressor upgrades

Minor modifications

Tie-ins to trunklines

Flange hook ups

Flowline projects

Commissioning and start up

Our Greenfield capability includes the following major projects:

CNG Stations

Pipeline Projects

Ras Laffan Helium Recovery Unit

Dukhan Flare Upgrade Projects

Diesel Filling Station and Mini Nitrogen Plant

Seawater Pump House

Saifee Engineering’s leadership in turnkey Design, construction, coupled with an unmatched legacy of field and technical support have been serving in the region as a recognized source for engineered storage tanks, vessels in industrial and Oil & Gas facilities for almost three decades, which makes Saifee Engineering a contractor of choice for the oil & gas midstream and chemical industries.Saifee Engineering’s installation base includes numerous tanks for Qatar Petroleum, Qatar Gas, OXY, DOLPHIN etc. The company employs state-of-the-art welding, painting, and fabrication equipment and facilities as well as advanced control and management technology to supplement the production of ASME and API certified steel and carbon tanks.Saifee Engineering’s production unit rolled out massive safe manhours for the production which included all types of tanks like:

Shop Fabricated tanks

Field welded storage tanks

Open top tanks

Fixed Cone roof tanks

Floating roof tanks (External, Internal, Domed external Floating roof tanks)

Underground Tanks etc

Regardless of the type of tank or industry served, our valued customers received and continue to receive the same high level of technical support, commitment to value and professional responsibility that ensures Saifee Engineering will remain their source for storage tanks and systems.

Leveraging our several years of experience as a system integrator and exposure to high profile turnkey projects has helped us master the skillset to offer solutions to the industry’s instrumentation & control requirements. Saifee Engineering has successfully positioned itself as a trusted Automation Contractor for the oil & gas industry in Qatar.Our past work history includes Design & implementation of PCS, DCS, Process Optimization System, ESD, ICSS, SCADA, PLC based systems, F&G Control Systems, Alarm Management System, etc. in Oil fields, Plants, Wellheads, Work Stations, Control Rooms spread across the country.Major projects executed include New Control Building at Halul Island, Automation upgrade at FM, FS, FN, FSP & NFIS in Dukhan Field.

Our role as a sole agent in Qatar for the world’s leading Automation Brand (Emerson) enables us to serve as a single source automation provider for your complete project and asset lifecycle.With our automation knowledge base continuously enhanced after every other project we completed, we are now capable to help the customers in understanding which systems suit their requirements the best, be it in the case of plant upgrade or new installations.Our automation Engineering and Design, Build and Maintain Services are targeted towards projects where oil & gas companies are looking for ideal instrumentation and safety system design consultants who can study their requirements and choose the best-fit package.

Saifee Engineering provides Engineering & Design Solutions and Engineering Management Services to clients. It provides quality engineering solutions in all engineering disciplines through its 30 plus strong specialists; possesses engineering software in its possession and has access to many industry-specific software.We offer our services under four broad classifications:Bid/Tendering Engineering, Detailed Design Engineering, Construction Engineering, Commissioning Engineering & Assistance. Our design and engineering services are fully tailored for projects in the Oil & Gas Industry. Our expertise and skills allow for fast-track project delivery through the application of high-end design tools such as PDS/PDMS that enable successive design and engineering phases integration. In this way, a new plant or facility is made operational in the shortest possible time.We offer multidisciplinary design and engineering services such as:

Process Engineering

Mechanical Rotating & Static Engineering

Piping & Pipeline Engineering

Civil & Structural Engineering

Loss Prevention Engineering

Electrical Engineering

Instrumentation & Control Engineering

Telecommunication Engineering

Construction Engineering

Commissioning Engineering & Assistance

Saifee Engineering’s electrical infrastructure solutions include the design of site-specific installations for different markets at every stage of engineering, procurement, construction, and commissioning.

Areas of EPC & Maintenance Expertise

Power Management Systems: Complete construction and erection management of power plants, substation design/build, electrical control rooms, generator houses, and gas turbine stations.

Building Services ELV: Structured cabling network, CCTV and access control systems, building management systems, TETRA and PAGA systems, fire alarm systems, fiber optics.

Manpower for Technical Solutions: Our in-house team of technical staffing professionals has extensive technical insight and in-depth knowledge of their specialist discipline in which they operate.

Cathodic Protection: Sacrificial, ICCP (impressed current) system and on-plot facilities/tank external CP systems, expertise in CIPS and Direct Current Voltage Gradient survey (DCVG).

PWHT: Welding preheat and post heat treatment for pipelines with a range of temperature programmers and controllers for setting and controlling the required heat treatment cycle.

Saifee Engineering has a solid foundation as an EPC Contractor to design, install and commission complete instrumentation package systems. And also provides lifecycle support services that include periodic proof testing, system maintenance, training programs on safety, code and standard compliance, and spare parts management.

Areas of Expertise

Control Systems Automation Upgrade: DCS with the latest Foundation Fieldbus-based DCS, ESD and F&G systems with certified SIL-rated systems, integrated turbine/compressor control systems with the latest state-of-the-art technology, and complete revamp on workstations.

Process Instrumentation and Analytics: Installation and commissioning of complete range of measurement instruments – Pressure, Temperature, Flow, Level, Positioners, and Analyzers.

Fire and Gas (F&G) Detection and Mitigation Systems: F&G system combines innovative fire and gas detectors, conventional and analog addressable fire panels, clean agent and inert gas fire suppression systems, and SIL-certified fire and gas systems.

Call off Services

Site operations are backed by our onshore fabrication facility and plant department, equipped with a fleet designed for live plant use. Our fabrication shop supports both onshore fabrication and offshore tie-ins handled by our site teams.

Shutdown Projects

Construction

- All type of Oil and Gas plant modifications

- Mechanical Rotating & Static equipment installation

- Shutdowns works

- Piping welding and installation

- Pipelines installation

- All Civil works including buildings roads, foundations etc.,

- Electrical wiring and termination

- Telecommunication equipment installation

- Critical activities execution such as hot taps

- Pre- Commissioning and commissioning support

Workshop Services

Covered Machine Shop Spanning 1,050 m², equipped with a 5T overhead crane.

Services include:

14” Hollow Spindle CNC Lathe Machines

Lathes (6” to 24”)

Horizontal & 60” Vertical Boring Machines

Radial Drilling, Mechanical Press, Shapers, Milling, Saws

We specialize in high-precision machining for API 5CT, API 6A, API 7-1 & API 16A products, Premium Connections, and Well Tubing & Casing Threads.

We follow strict safety protocols like PTW (Permit to Work) and LMRA (Last Minute Risk Assessment) to ensure top quality and safety. Real-time monitoring is handled through our SAP system. We comply with major international standards (ASME, API, AWWA, ASTM, etc.) to meet diverse client needs.

WE ARE EXPERT IN BELOW SERVICES

Pipe Fabrication

Structural Fabrication

Tank/Vessel Fabrication (ASME and Non-ASME)

Welding Services

Pressure & Proof Load Testing

Industrial Painting Services

PIPE FABRICATION

Pipe fabrication is one of our key strengths. Our skilled team ensures high safety and quality, delivering greater efficiency and cost savings. We exceed expectations in design, logistics, schedule, and performance.

Materials handled:

Carbon Steel

Alloy Steel

Stainless Steel

Austenitic Stainless Steel

CuNi Alloys

STRUCTURAL FABRICATION

We manufacture steel structures for projects of all sizes. Our systems follow ISO9001, ISO14001, OHSAS-18001, and LR standards to ensure safety, quality, and environmental compliance.

We fabricate:

Pipe Racks

Heavy/Medium Platforms

Steel Racks, Ladders, Supports

Secondary Steel Structures

TANK/VESSEL FABRICATION

We offer reliable tank and vessel fabrication for industrial use. Our in-house engineers and project managers ensure smooth execution and structural integrity.

Types:

ASME/Non-ASME Vessels

Pressure Vessels

Storage Tanks

Used in:Chemical, Petrochemical, Petroleum, Water sectors

WELDING SERVICES

Our facility uses modern welding equipment offering services like TIG (GTAW), MIG (GMAW), Stick (SMAW), Flux Core (FCAW), and Submerged Arc Welding (SAW). We deliver quality welding that meets ASME and U.S. standards with minimal downtime.

PRESSURE & PROOF LOAD TESTING

We provide hydro testing for cylinders, pipes, and joints, conducted by qualified staff in a dedicated facility. Proof load testing is verified by certified third-party inspectors like:

BUREAU VERITAS

GERMANISCHER LLOYD

TUV NORD

INDUSTRIAL PAINTING SERVICES

We offers blasting and industrial painting in a controlled environment. Our sandblasting system ensures clean, efficient, and eco-friendly results. We prepare, coat, and paint all fabricated items in-house as per client specs, with proper preservation during delivery.

With over 12 years proven experience within the Electric Motor repair industry, Doha Petroleum are proud to be recognized as the ‘Best in the Business’ when it comes to High and Low Voltage Electric Ex and Non-Ex Motor Repairs. Our purpose-built unit offers a unique facility specially designed to complete repairs up to 16MW motors and high voltages performance test run up to 14.4 KV. Our aim is to provide our customers with the support they need to maintain their plant during breakdowns and planned maintenance. Our commitment to re-invest means we can repair at the most competitive prices within the industry.

Our workshop is based in Salwa Industrial area, Doha, Qatar well-equipped to service rotating machinery equipment (Motors and Pumps) with a quick turnaround time. We meet ISO 14001, 45001 and IECEx service standard requirements. We are certified member of AEMT and EASA and provides repair service as per IEC 60079-19. We currently perform round the clock services for major clients (Qatar Petroleum QP, Qatar Fuel Additives Company QAFAC, WOQOD, Mesaieed Power, GE field core, Samsung) in Qatar.

- Large High Voltage motors rewinding and overhauling

- High Voltage motors rewinding and overhauling

- No Load test tun up to 14.4 KV voltage rated

- Reliability and Vibration Analysis

- Dynamic Balancing of Rotors

- Core loss testing, Hot spot tests & Rotor/Armature testing

- 15KV Partial Discharge testing and Surge Testing

- All DC tests (IR, PI, PA, DC step) and RLC capabilities

High Voltage Motor Services

Complete HV motor overhauls, rewinds (up to 16MW / 14.4KV) per ISO & AEMT standards with full documentation.

Pump Refurbishment

Expert pump repairs & overhauls, with in-stock seals, bearings, and gaskets for quick service.

Maintenance & Site Support

Experienced engineers available for on-site breakdown response and scheduled maintenance. We ensure top performance and HSE compliance.

Accurate Calibration Services for Instruments, Test Meters & Gauges

Our ISO 17025 accredited calibration laboratory is able to facilitate the calibration of a wide variety of testers ranging from electrical meters, such as multimeters and clamp meters, to specific testers such as barometers, vacuum gauges, anemometers, digital thermometers and much more. We also calibrate several tools including torque screwdrivers and wrenches, steel rules, theodolites and vernier calipers. Saifee Engineering is certified to carry out calibration services for a wide range of instruments, (pneumatic to smart type), with the following ranges: Pressure -0.8 to 20 bar pneumatic & 0 to 1,400 bar hydraulic, Temperature -350C to 1,1000C, Thermocouple calibrator -2000C to 1,3700C

Dimensional Calibration

Gauge Calibration – Tool Calibration – Mechanical Calibration

Our accredited dimensional calibration laboratory caters for standard mechanical gauge and tool calibration, such as micrometer calibration, thread gauge calibration, or calibration of gauge blocks.

Electrical Calibration

Meter Calibration – Tester Calibration – Electrical Stds

With an electrical calibration capability on frequency up to 20GHz, voltage up to 40kVDC and current up to 1000ADC, we can provide calibration on most types of DC or LF electrical tester or meter, from handheld field instruments to laboratory standards.

Bench type equipment such as counter timers, long scale multimeters, oscilloscopes and power supplies are also covered by our electrical accreditation.

Force Calibration

Force Gauge, Load Cell, Scales and Weight Calibration Services

In our calibration laboratory for mass we can weigh dead-weight tester masses from 0.1g to 20kg with uncertainties of 0.5mg, 15mg and 0.0003 % of reading, depending on the mass range. For the calibration, in our calibration laboratory, we only ever use high-accuracy electronic mass comparators and reference weights.

Pressure Calibration

Pressure Gauge Calibration – Instrument Calibration Services

In our calibration laboratory for pressure we calibrate measuring instruments in the measuring range from 10 mbar absolute … +5,000 bar gauge with uncertainties of 0.004 % … 0.01 % of reading, depending on the pressure range. For the calibration, in our calibration laboratory, we only ever use high-accuracy references such as dead-weight testers, digital piston gauges and pressure controllers.

For dead-weight testers we offer two types of calibration – ‘pressure equivalent calibration’ where we compare the pressure generated by a dead-weight tester against a reference standard at a number of points over the range or ‘area calibration’ where we determine the effective area of the piston-cylinder unit over the range of the instrument.

Temperature Calibration

Contact Thermometer and Infrared Thermometer Calibration

Our temperature laboratory uses a range of reference platinum resistance thermometers, noble metal thermocouples, stirred liquid baths, specially designed isothermal calibration furnaces and black body sources to provide a comprehensive facility for cost effective thermometer calibration or temperature probe calibration over the range -80ºC to 1,200ºC. We can even calibrate temperature sources such a dry block calibrators or calibration baths.

Torque Calibration

Torque Wrench Calibration – Torque Tool or Meter Calibration

Regular torque tool calibration ensures repeatable accuracy and adherence to international standards. In addition to torque wrench and screwdriver calibration we also calibrate a wide range of other equipment’s like torque closure meters, analyzers etc.

Valve Repair & Overhauling

| Type of Valve | Pressure Class / Size | Type of Valve | Pressure Class / Size |

|---|---|---|---|

| Ball Valve, Gate Valve | 150# to 2500# up to 42” | Conventional SRV | Size: Up to 18” |

| Globe Valve, Check Valve | 150# to 2500# up to 24” | SRV with Bellows | Size: Up to 18” |

| Choke Valve | 150# to 2500# up to 12” | Pilot Operated SRV | Size: Up to 18” |

| Butterfly Valve | 150# to 2500# up to 60” | Pilot Op Vacuum Valve | Size: Up to 24” |

| Needle Valves | Up to 10000PsiG | PCV | Any Size |

| Control Valve | 150# to 2500# up to 36” | Tank Valves | Size: Up to 24” |

| ESDV, SDV, MOV, Hyd. op | 150# to 2500# up to 42” | PVRV | Size: Up to 24” |

| Dual Plate Check Valve | 150# to 2500# | DBB, Penstock, ACV | Any size |

| Hydrostatic Testing (Water) | Up to 10000Psig | Air / Gas Testing | Up to 5000Psig |

Saifee Eng is well equipped to carry out following activities.

- Dismantling and cleaning of valves

- Visual and dimensional inspection

- HP water jetting

- Machining and lapping

- Grit blasting / Spray painting

- Lathe and boring machines

- Valve Grinding and lapping machines

- Assembling and pressure testing

- Hydro test pumps and chart recorders

- Gas boosters and Rota meters

- Control valve and PSV testing machines

- Online PSV Calibration (In-site testing machine)

- Portable lapping/grinding Machine

- Offshore & Onshore mobilization of valve technician

- Hydrostatic testing of Fabricated Spools & vessels

- Final painting

Overhauling of actuated valves

Online PSV/RV Test Facility

- It is compact in size. Very easy to carry to work at height

- Set pressure verified online without stopping the process

- Operating Limits 0.01KN TO 50 KN

- It suits to all manufacturer and any size of RVs

CV Calibration by using HART

Testing of ESDV Valve

Valve Leak Testing in Progress

Dismantling of Actuator

Ball Valve Dismantled

64” BFV Testing

Dismantling of Valve

Measure and Record details

PSV Testing on Computerized Machine

Computerized Testing Control/Stop Valves

Inside View with Crane

Lathe Machine

RV Computerized Testing

Computerized Test Set Up

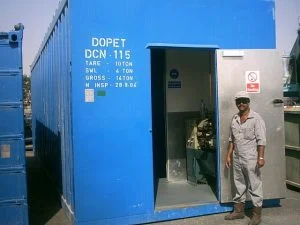

Mobile Workshop